Valet av driftsförhållanden under en kristallisationsprocess har en direkt inverkan på viktiga produktattribut som kristallstorlek, kristallform och renhet. Genom att förstå kristallisationsprocessen och välja rätt processparametrar, är det möjligt att på ett repeterbart sätt skapa kristaller med korrekt storlek, form och renhetsgrad, samtidigt som man minimerar nedströmsproblem som långa filtreringstider eller otillräcklig torkning.

Hur kan vi hjälpa dig?

Vägledning till effektiv processutveckling

Denna white paper-serie täcker grundläggande och avancerade strategier för optimering av kristallstorlek och formfördelning.

Fallstudier om kristallisationsutveckling

Kristallisationslitteraturen är full av exempel på hur standardverktyg för kristallisation har använts för att på ett framgångsrikt sätt förbättra både kristallprodukter och processkvaliteten. Journaler, white papers och webbseminarier från akademier och branschen hjälper kristallisationsforskare att utveckla och dela nya idéer.

Övervakning, optimering och kontroll

Användning av kristallisationsenheter erbjuder en unik möjlighet att rikta in sig på och kontrollera en optimerad kristallstorlek och formfördelning för att:

- Reducera filtrerings- och torktider

- Undvika problem med förvaring, transport och hållbarhet

- Säkerställa en konsekvent och repeterbar process till lägre kostnad

Realtidsmikroskopi

För kristaller, droppar och partiklar

Denna 7-minuterspresentation beskriver hur man visar partiklar i realtid för att få en bättre processförståelse.

Applikationer

Application Guide to Crystallization Development and Scale-up

Trycksaker

Crystallization and Precipitation Engineering Case Studies

Relaterade produkter

Technology for Crystallization Development and Scale-up

Particle Size Analyzers

Understand, optimize, and control particles and droplets in real time with in-situ particle size analyzers.

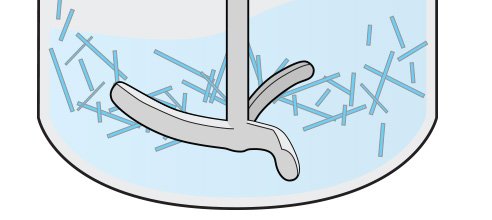

Chemical Synthesis Reactors

Increase productivity in your lab with chemical synthesis reactors featuring built-in automation tools.

ReactIR

In-situ FTIR spectrometers enable scientists to gain insight into their reactions and processes in a wide range of applications. Optimize reaction variables with inline FTIR instru...

ReactRaman

ReactRaman enables scientists to measure reaction and process trends in real time, providing highly specific information about kinetics, polymorph transitions, and mechanisms.

Scale‑up Suite

The world’s leading process development and scale-up software for scientists and engineers.