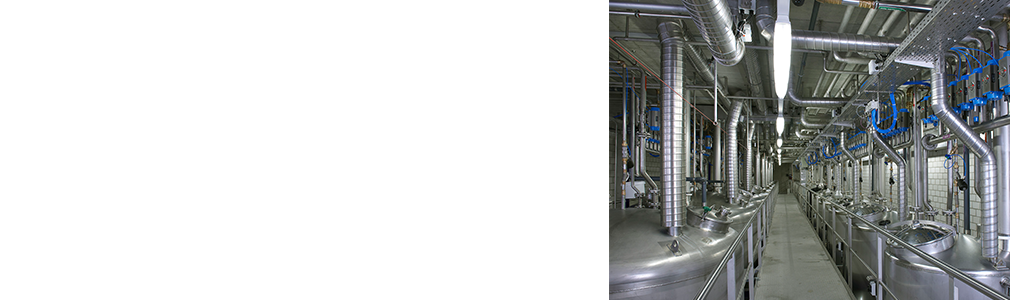

Gravimetric level control is one of the most accurate inventory control methods available for measuring high-value solids, liquids and even gases inside tanks. Tank load cell is placed outside of the tank, which makes them superior to other measuring methods for aggressive, hot, frozen, non-free-flowing or non-self-leveling materials. Measuring results are not impacted by tank shape, load cell materials or process parameters, such as temperature or material viscosity.

Accurate Inventory Control

Compression Weigh Modules

Most tanks holding 10 kilograms to 1,000 tons or more are mounted on compression load cells or compression weigh modules for weighing. The RockerPin ensures the best accuracy in case of thermal expansion or contraction. Compression weigh modules are ideal for turning tanks into tank scales. In addition, smaller tanks can be mounted on bench or floor scales, which is convenient for legal-for-trade applications.

Suspended Weigh Modules

Tanks or hopper scales can be suspended from tension load cells or weigh modules, with accuracy similar to that achievable with compression systems. This mounting method can be convenient if an overhead structure already exists, or if the ground space under the scale must be kept clear. It is applicable for scales with capacities of approximately 20 kilograms (45 lbs.) to 30 tons.

Protected Load Cells

Outdoor tanks must have safety features to protect the load cell during installation and operation. Tanks are exposed to wind forces. This requires features for weigh modules to cope with uplift forces on one side and extreme load on the other. Temperature changes can result in expansion and contraction of the support structure. Our weigh modules are designed to cope with such circumstances.

Online Status Information, Easy Cabeling

Weigh modules with POWERCELL® technology reduce downtime with predictive maintenance. A run-flat function allows you to continue a batch in the event of a damaged load cell or a broken connecting cable. A daisy-chain-type network technology with plug-and-play connectors eliminates the need for junction boxes, which can be prone to damage. The CalFreePlus™ feature eliminates need for re-calibration in the event the cables or load cells have to be replaced.

Safety Tested with Full Load

METTLER TOLEDO weigh modules are designed to mitigate uplift forces resulting from wind and earthquakes and temperature-related expansion and contraction of the tank's support structure. We perform Finite Element Analysis on mechanical parts and perform tests to expose even heavy-capacity weigh modules to real-life conditions with full loads.

Publications

White Papers

Brochures

Guides

Webinars

Related Products

Weigh Modules, Load Cells, Load Sensors

Industrial Floor Scales & Heavy-Duty Scales

Scale Indicators, Weighing Controllers and Transmitters

Service

Professional Installation and Setup

METTLER TOLEDO's StarterPac is designed for professional product installations and solid user familiarization in lowly regulated or unregulated environments. This ensures direct deployment, immediate use and optimal productivity right from the start.

The IPac is designed for regulated industries with the need for assurance that products are safe and of consistently high quality. This ensures peak performance and thoroughly documented compliance with internal standards and external regulations.

Innovative RapidCal™ Tank Scale Calibration

Calibrate Faster

RapidCal™ Tank Scale Calibration equipment is highly portable and requires minimal preparation time and effort in use. Loading and calibration are done quickly, resulting in lower downtime over the course of a year. How much would your business save by reducing production shutdowns for calibration?

High Accuracy

The calibration force applied by hydraulic cylinders is measured by highly accurate reference load cells whose calibration is traceable to test weight standards. The process pulls down on the scale identically to normal weighing, thus automatically accounting for piping effects.

Preventive Maintenance Ensures Consistent Performance

This service provides you with periodic, preventive maintenance according to the frequency of equipment use and process risks to avoid unexpected equipment downtime and ensure continuously accurate and reliable operations including:

- Data backup and storage

- Inspection and cleaning

- Calibration and adjustment

- Documenting equipment condition

- Service recommendations

Tank Scale Health Inspection

METTLER TOLEDO's Tank Scale Health Inspection service is an equipment inspection that proactively discovers issues before they cause unexpected downtime or quality problems. Upon completion of the health inspection, a detailed report will be provided to you that contains the scale’s condition and any associated service recommendations.

A Tank Scale Health Inspection provides information on:

- Status of load cell, force introduction, junction box and wiring

- Performance reducers such as piping, wiring or environmental impacts

Consulting for Evaluation and Design Review

As time and budget are often limited, you may not always have the in-house expertise or capacity required to evaluate adequate equipment or review your design before going to production. You may require assistance with:

- Analysis and documentation of requirements

- Ensuring best design for achieving required weighing performance

- Ensuring compliance with standards and regulations

- Evaluating safety risks during installation and operation

Upgrade Existing Equipment

Existing tank, silo, hopper or vessel scales can be upgraded with modern weighing equipment to improve accuracy, reliability and uptime:

- Real-time diagnostics for predictive maintenance

- Higher accuracy thanks to modern weighing technology

- Easy to replace load cells and cables with plug and play connectors

- Overload stops provide more safety in cases of strong wind and earthquakes

Standard and Customized Training

We offer a wide range of training programs tailored to fit the needs of designers and installers of the tank manufacturers as well as the maintenance of the end user. Our experts around the world provide know-how such as:

- Understanding principles of metrology

- Design considerations for tank, silo, hopper or vessel scales

- Maintenance of equipment to ensure performance

- Safety precautions during installation and repair

- Competence testing and certification

Repair Service to Restore Performance

Rely on the manufacturer's competence for fast, reliable repair services performed by certified METTLER TOLEDO Service Technicians with the right skills, tools and original spare parts to ensure that:

- Error diagnostics isolate the root cause

- Problems are solved correctly the first time

- Equipment is re-configured to ensure return to previous performance

- Future problems can be avoided