Watch this video to learn how automated in-line vision inspection systems can check cap presence, quality or colors and check for over- or under-filled products.

Cap & Fill Level Vision Inspection Systems

Verify cap application, integrity and fill levels

Guide to Cap and Fill Check using Vision Inspection Systems

Cap Presence and Positioning Applications

A missing or cocked cap on a product package can result in unnecessary product waste and costly rework, which leads to lost profits. Our systems quickly identify products with missing or improperly-applied caps, removing them from the production line and alerting operators to the issue. Systems can also verify the correct color of cap is present, should different cap types or colors indicate different product varieties.

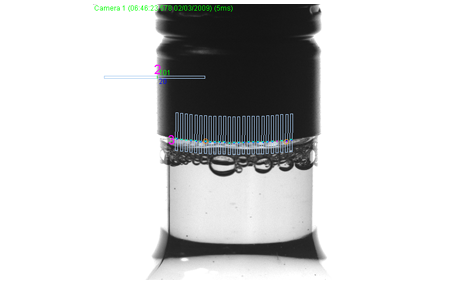

Fill Level Detection

Unnecessary product giveaway is a source of lost profit, and under-filled products can result in trouble from government regulators. Along with cap presence and positioning, our vision systems are also capable of performing fill level inspection on clear and tinted bottles in order to ensure that all packages have been properly filled.

Tamper Band Inspection

For many products, a tamper-evident device provides reassurance to consumers that the product has not been altered in any way. The lack of such a band damages consumer confidence, and results in returns and rework - and for some products, the presence of a tamper band is required. Our systems help verify the presence of a properly-affixed tamper band on every product.

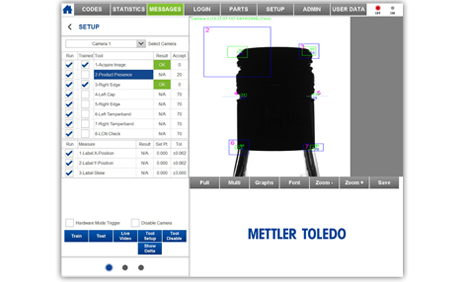

Smart Cameras and PC Based Vision System

Simple presence of caps or tamper bands can be handled quickly by a smart camera, but depending on the quality inspections desired, additional processing power would be necessary. In that case, a PC-based inspection system can provide high throughput speeds without sacrificing accuracy. If you are unsure which to choose, our experienced team can help determine the best solution for your needs.

Download Comparison of Vision Inspection Systems Infographic:

FAQs

How does a missing cap actually happen?

There are plenty of reasons something can go wrong, particularly in a high-speed production environment. It could be an insufficient number of caps loaded into the filler, or an unexpected problem with the feed, or some other mechanical issue. It happens more often than you might think, and it is inevitably a headache for operators when it happens. Being able to instantly alert operators when caps start going missing is critical.

Do I need a stand-alone system to check for caps?

No, you really do not need a stand-alone system to check for caps. There are a couple ways to go about this, depending on what your priorities are. If you are only concerned with cap and fill level, you can integrate a smart camera (or a PC-controlled camera) into your existing filling equipment. We have experience with producing integrated solutions, and are happy to lend our expertise and equipment in setting something up. You can find out more about our custom solutions by contacting us or visiting our custom solutions page.

What else can I do while I'm inspecting caps?

The most convenient part of a vision inspection system is its ability to carry out simultaneous inspections of other package elements. A single shot of the package can be used to perform multiple inspections – most simply, a picture used for cap inspection can also ensure the presence of a tamper evident band (if one is used) and verify the fill level. Calibrated correctly, the same image can be used to perform inspections on the package label, although depending on the package shape it may be necessary to use a multi-camera configuration.