Completeness matters for manufacturers of parts, modules and kits to ensure customer satisfaction and to avoid expensive rework or return of delivered goods. But completeness also matters in the production process to avoid adding value to defective semi-finished products in subsequent manufacturing steps. Weighing is a simple and fail-safe method for in-process or end-of-line quality control where high-precision scales can detect deviations of 0.001 percent within a split of a second.

Avoid Expensive Rework

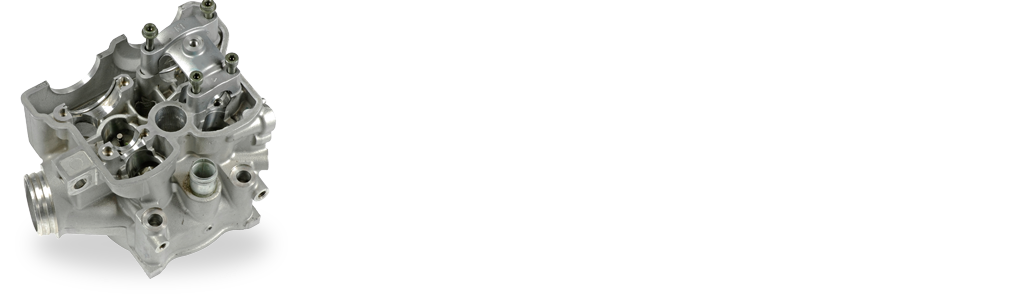

Integrity Verification for Complex Structures

Cavities, missing sections in complex structures and density deviations harm quality of tool-shaped parts from injection molding, die casting, powder-metal pressing, sand casting and stamping. The smallest weigh deviations can identify potentially defective products that need further inspection. METTLER TOLEDO has weighing technology with repeatable resolution of up to 4 million points to reliably detect smallest deviations.

Completeness Control for Kits

Repair, toy or mounting kits often consist of very small and very large parts of different materials, including documentation. Visual completeness control is not effective for checking completeness of parts inside non-transparent packages or when parts are stacked. High-precision weighing can verify completeness despite poor visibility. METTLER TOLEDO offers many solutions from static scales, conveyor scales or weigh modules to incorporate into a machine.

Completeness Control for Modules

Functionality tests of gear boxes, ball bearings or electromechanical devices do not always detect all the errors that might affect their lifetime. Incorrect oil quantity or missing parts often pass unnoticed in short-term functionality tests. Weighing is a simple-to-apply method for a complementary completeness check, even for products that include movable elements. High-capacity weighing with the highest resolution allows verification of even heavy products.

Gravimetric Verification for Volumentric Filling Processes

In manufacturing of pharmaceuticals and cosmetics, verifying volumetric filling by weight is the preferred method because it is directly traceable to a standard. However, the method of gravimetrical quality control is not limited to the quantity of the product. It also verifies presence of accessories. such as spoons and cups or brushes. Our weighing technology combines 100% control and high throughput.

Automated Tablet or Capsule Testing

Weight is an important quality parameter for tablets and capsules. Manufacturers either test samples or every tablet. METTLER TOLEDO has dedicated ultra-small weigh modules for compact instruments for sample testing or machines for high throughput when 100-percent control is required.

Verifying Coating and Etching Processes

Products, such as solar wafers, go through several manufacturing steps in which material is added or subtracted. Simple weighing before and after treatment is all that is needed for in-process quality control. High-precision weighing is a simple non-destructive method to verify coating or etching processes. METTLER TOLEDO has a global team of experts that support machine builders and end users in applying weight for manufacturing of all types of electronics.