A repeatable formulation process starts with accurate weighing. Simple paper-based operations can be enhanced with scale terminals that feature visual tolerance indication with weighing bars and color displays. Documentation and traceability are achieved by attaching a printer to record actual material quantities.

Formulation Solutions

Only accurate, repeatable and error-free formulation processes ensure perfect batches.

Review our four formulation solutions and see why choosing the right equipment pays off!

Speed Up Simple Formulation Processes

The ICS689 is a stand alone formulation work station that offers:

- Guides an operator through a recipe

- Provides traceable recipe weighing

- Can handle up to 50 recipes with up to 50 components each

Make Every Batch Perfect

Form+ is a recipe management software that offers:

- Easy adaptation of your processes with no limits on formulas

- Tools to ensure safe, correct and traceable recipe execution

- Connectivity to multiple bench and floor scales

Formulation software: www.mt.com/Formplus

Bench platforms: www.mt.com/ind-platforms

Ensure Accurate and Fast Dosing

The IND570 filling and dosing terminal supports:

- Easy-to-configure software routines, or material storage tables

- Connectivity to Powerdeck floor scales for optimal operator guidance

- Multiple PLC interface options, along with sample programs such as Rockwell Automation profiles

Dosing terminal: www.mt.com/IND570

Floor scales: www.mt.com/Powerdeck

Ensure a High Batching Yield

The IND780batch terminal offers:

- Storage for up to 1,000 recipes with as many as 99 steps per recipe

- Multiple interface options for tracking and tracing

- An ideal combination with PowerMount Weigh Modules to avoid bad batches in tank weighing applications

Batching terminal: www.mt.com/IND780

Weigh modules: www.mt.com/ind-powermount

Simple Formulation

Terminal-based Recipe Management

Scale terminals with integrated recipe management provide an additional level of process control in a compact package. Raw materials, lot numbers, and operator messages can be stored for easy operator recall. Confirmation of process steps with a connected barcode reader ensures the production is both comfortable and secure.

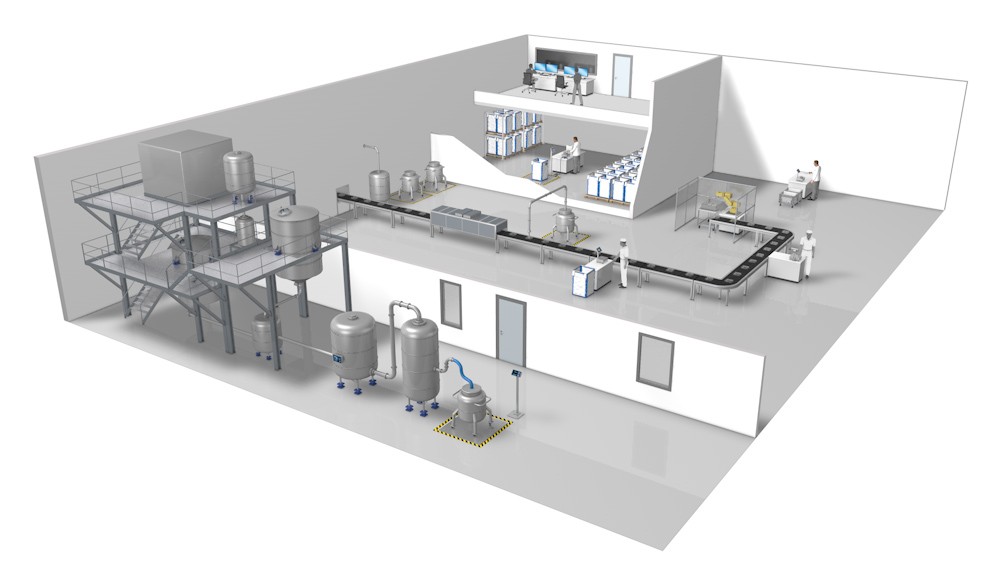

Formulation Software Solutions

Whether production requires manual or automatic dispensing, or a combination of the two, centralized formulation systems can unite workplace flexibility with rigid process control. Configurable software and operator friendly workstations can optimize the weighing process to eliminate errors, streamline utilization, and reduce material waste. Incorporation of industry standards, such as S88, integration with ERP systems and validation support for regulatory environments ensure a complete and robust solution.