Influence of Absorbed Moisture on the Mechanical Properties of Polyamide 6

Introduction

Water behaves as a plasticizer for many amorphous and semicrystalline plastics. Technically relevant mechanical material parameters such as the elastic modulus and the glass transition temperature vary quite significantly depending on the moisture content (water content) of a material. Examples of plastics that spontaneously absorb moisture (water) from their surroundings are hygroscopic epoxy resins, polyurethanes, ABS polymers, polycarbonates and all polyamide derivatives.

This article describes measurements of Polyamide 6 (Nylon 6) and shows

- how dynamic mechanical analysis can be used to determine the dependence of the elastic modulus and the glass transition temperature on the absorbed moisture content

- how the equilibrium (maximum) moisture content and the moisture uptake rate can be determined at different relative humidity levels and temperatures, and

- what conclusions can be drawn for correct sample conditioning in a humid environment.

Sample Material: Polyamide 6

Polyamide 6 samples (GoodFellow), 1 mm thick, 3 mm long and 3 mm wide, were used for all the DMA, TGA and sorption experiments.

This sample geometry corresponds to that typically employed for these techniques. The samples were dried under vacuum (0.1 mbar) at 60 °C for 24 hours in order to obtain defined starting material. The loss of mass of samples through drying was determined by TGA and was found to be less than 0.1% up to 240 °C (melting range endset: 230 °C). The dry samples were sealed airtight and stored at 25 °C until use.

Sample Conditioning in Desiccators

Samples were conditioned in desiccators at different relative humidity levels in order to obtain samples of different well-defined moisture content. The relative humidity (RH) in the individual desiccators was established using supersaturated solutions of sodium chloride (75% RH), sodium bromide (58% RH), potassium carbonate (43% RH), potassium acetate (22% RH) and pure water (100% RH).

Summary

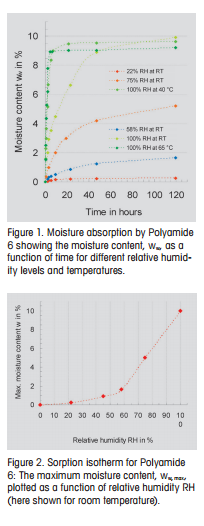

Depending on the relative humidity, dry Polyamide 6 can absorb up to 10% by mass of moisture from its surroundings. This influences the glass transition temperature and elastic modulus of the material. The resulting effects were studied by first conditioning samples at different relative humidity levels (between 0 and 100%). This was done in desiccators containing different supersaturated saltwater systems. The maximum or equilibrium moisture absorption of a sample depends mainly on the relative humidity of the surroundings and to a lesser extent on temperature. Moisture absorption up to the maximum moisture content takes about 200 hours, independent of the particular relative humidity concerned. To exclude the possibility of measuring the properties of inhomogeneous samples, sufficient time must be allowed for the sample to attain its maximum moisture content before or during the measurement.

Dynamic mechanical analysis, DMA, of samples that had been conditioned to maximum moisture content shows that a moisture content of 1.0% lowers the glass transition temperature from 60 °C to 30 °C. The glass transition temperature of Polyamide 6 with the maximum possible moisture content (conditioning at 100% RH) is −25 °C. The elastic modulus of a sample with the maximum moisture content is about four times less than that of a sample in the dry state. In the glassy state, the material stiffens linearly with increasing moisture content and finally has a value twice that of the dry material. The modulus value after the glass transition is practically independent of moisture content. Furthermore, TGA/SDTA851e and DMA/SDTA861e experiments showed that the loss of water from the sample during a measurement is so small that the measured values are not affected. Consecutive measurements of the same sample showed that the glass transition temperature did not change. In conclusion, one can say that

- Samples must be conditioned at a defined relative humidity sufficiently long for the sample to attain a homogeneous distribution of moisture in the sample.

- In a DMA measurement, there is no need to protect the sample against loss of moisture. There is therefore no advantage in performing measurements under conditions of defined relative humidity in the measuring cell as is sometimes recommended

Relative Humidity

The relative humidity (RH) is the ratio, p/p0, of the water vapor pressure, p, (partial pressure) in a sample of moist air to the saturation water vapor pressure (p0) at the same temperature expressed as a percentage. For example, at a relative humidity of 50%, air contains only half of the maximum amount of water vapor it could hold at that particular temperature. At 100% relative humidity, air holds as much water as it possibly can, i.e. it is fully saturated with water vapor (Fig. 10). If 100% saturation is exceeded, the excess moisture precipitates as condensation. The amount of water vapor needed to attain saturation increases with increasing temperature because the saturation water vapor pressure, p0, of air increases exponentially with temperature. For example, at normal pressure, a cubic meter of air at 10 °C can hold 9.41 g water. At 30 °C this value is already 30.38 g water. Since the maximum amount of water that air can take up changes with temperature, it is essential to state the temperature when quoting values of relative humidity.

Influence of Absorbed Moisture on the Mechanical Properties of Polyamide 6 | Thermal Analysis Application No. UC 241 | Application published in METTLER TOLEDO Thermal Analysis UserCom 24