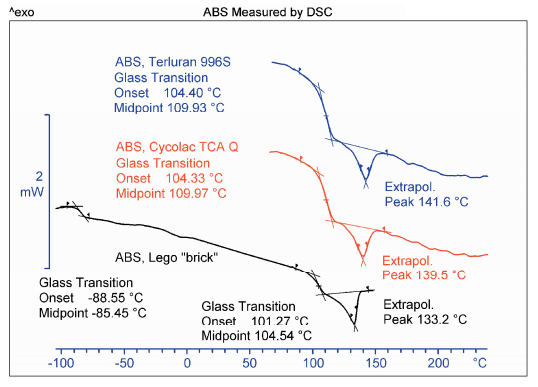

ABS Glass Transition by DSC

Sample

Terluran 886S, Cycolac TCA Q, Lego "brick", Novodur P2M and Magnum 3416 HH

Conditions

Measuring cell: DSC20

DSC821e with liquid nitrogen cooling

Pan: Aluminum standard 40 μl, pierced lid

Sample preparation: Disk cut from pellet or injection-molded part

DSC measurement: In a first heating run, the thermal history is eliminated by heating from 30 to 250 °C. After uncontrolled cooling to room temperature, the actual measurement is performed at 20 K/min in the DSC20 and at 10 K/min in the DSC821e. With the latter, the initial temperature was -150 °C.

Atmosphere: Nitrogen, 50 cm3/min

Evaluation

The table lists the glass transition temperatures as midpoints.

Interpretation

The most pronounced thermal effect of ABS is the glass transition of the polystyrene component around 100 °C. In the low temperature range, DSC can also detect the polybutadiene transition. Above 100 °C. In the low temperature range, DSC can also detect the polybutadiene transition. Above 100 °C, there is a peak caused by the polyacrylonitrile. Since it is a peak rather than a change in cp, the peak temperature is recommended for characterization. ABS with a very low content of polyacrylonitrile does not exhibit this peak.

Note: some authors interpret the peak around 130 °C as being due to melting of slip additive or mold lubricant.

Conclusion

The DSC curves of the ABS samples are different and can be used to characterize the materials. DSC is therefore a good method for the quality control of incoming ABS material.

ABS Glass Transition by DSC | Thermal Analysis Handbook No.HB251 | Application published in METTLER TOLEDO TA Application Handbook Thermoplastics