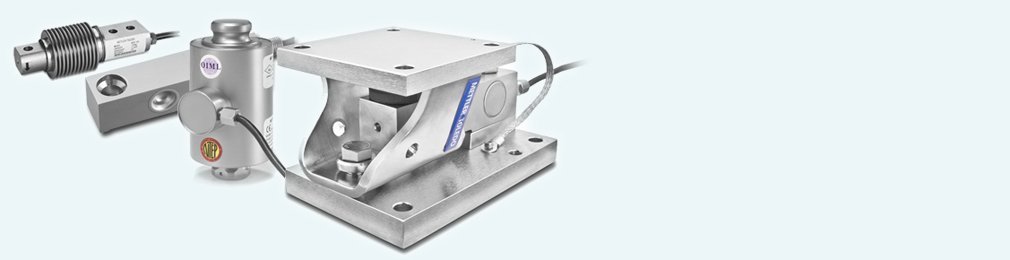

Weigh Modules, Load Cells, Load Sensors

Tailored to The Needs of Machine and Instrument Manufacturers

Weigh modules and load cells enable the quick and safe conversion of tanks, vessels, silos, hoppers, conveyors, or other structural systems into scales. Built-in side-load and anti-lift protection ensure that safety, performance, and precision are maintained. METTLER TOLEDO offers a wide range of weigh modules with capacities from 5 kg up to 300 t.

Explore our Services - Tailored to Fit your Equipment

We support and service your measurement equipment through its entire life-cycle, from installation to preventive maintenance and calibration to equipment repair.

Support & Repair

Maintenance & Optimization

Calibration & Quality

Training & Consulting

Professional Installation - Get it right from the start

FAQs

Discover a Range of Industrial Weigh Modules and Load Cells

METTLER TOLEDO weigh modules, or weighing modules, are used in food, pharmaceutical, and chemical applications. They are available in various versions depending on the application and environment to meet the requirements of OEM machine manufacturers, system integrators, and end-users. Weigh modules incorporate SafeLock for fast and safe installation. The weigh module is locked and acts as a solid block protecting the load cell sensor from overload during installation.

A wide range of accessories are available for weigh modules including stabilizers for use with aggressive mixers and agitators, thermal pads to isolate from conducted heat, and shock-vibration pads to dampen shock and vibration. Dead stands for level-control applications are also available.

METTLER TOLEDO offers a wide range of weighing modules from 5 kg up to 300 t capacity. Weigh modules are available in painted steel, zinc-plated steel, 304 (1.4301) stainless steel and 316 (1.4401) stainless steel electro-polished. They are available in various legal-for-trade accuracy levels according to OIML R60 and NTEP HB44 starting from OIML 3000e (OIML C3), NTEP 5000d, OIML 6000e (OIML C6), NTEP 10000d to finally OIML 10000e (OIML C10). Weigh modules are available for hazardous area applications and are approved according to ATEX, FM (Factory Mutual), cFM (Canada), IECEx, and NEPSI. They meet protection classes IP67, IP68, or even IP69K. Weigh modules are available in EN1090 versions made in specially controlled and documented manufacturing processes for high safety requirements. Weigh modules support the weightless calibration CalFree or even CalFree Plus allowing for tank calibration on a fingertip.

What is the difference between a weigh module and a load cell?

If we look at this question in simple terms, this can be easily explained. Put simply, a weigh module takes a non-traditional structure and turns it into a scale. And a load cell or load cell sensor is what is found within every 'traditional scale' – let's break that down a little further.

A weigh module takes a non-traditional structure, most commonly a tank, and turns it into a weighing device. This means, when we add weighing sensor modules underneath tank legs, the tank goes from just a structure that was holding a substance, to a weighing structure that is measuring how much substance is within the tank itself.

A load cell, in simple terms, is the heart of every standard scale. Load cells are found in all scales, from a highly sensitive lab balance to a heavy duty floor scale, and everything in between. Load cell sensors are what take a scale from just a platform and turn it into a sensitive weighing device.

Why should I choose METTLER TOLEDO as my weigh modules and load cell provider?

METTLER TOLEDO takes a consultative approach to all projects. Our team of expert sales and service technicians work hard to ensure you get the solution that is fit for your purpose, with the required accuracy and durability for your application.

What is a load cell and how does it work?

The basics of load cell technology is converting a load - which is a force applied to any mass in the earth gravity field – into an electrical signal. Most load cells have so called load cell sensors that convert a mechanical strain into a resistant change. Learn more on load cell sensors below. The mass applies a load enforced by the gravity field, that load stresses the body of the load cell and lead to deformation – strain. The load cell sensor is converted into resistant change and finally into a voltage output. That output is proportional to the applied mass.

A scale load cell, or load cell sensor, is used in variety of industries in which precise measurements are needed. Load cells accurately measure the weight of tanks, vessels, hoppers or conveyors. Load cells are built to withstand the demands of a variety of rugged industrial applications. The capacity of load cells can greatly vary. Some load cells are more appropriate for laboratory applications, while others are more appropriate for high-capacity batches or logistics applications.

Load cells shall meet all globally required approvals and standards. They include electronic load cells, analog load cells, and hydraulic load cells that allow you to change your structure into a scale. Load cells are used in floor scales, belt weighers, weighing systems, pallet scales, checkweigher scales, load cell scales, and conveyor scales. Loading cell technology from METTLER TOLEDO features robustness for harsh environments as well. These are typically used in tank scales, vessel weighing, silo scales and truck weighing.

How do you design a load cell?

Their form first distinguishes load cells. Single-point load cells are used for small and mid-size applications. Strain gauge load cells are used for floor scales and mid-size tank scales. Canister load cells are used for heavy-capacity applications. Another separation criteria for load cell types and uses is the output provided. Analog load cells need an external terminal for amplification and A/D conversion while digital load cells or electronic load cells have in-built "intelligence" with the advantage of better accuracy, much more robust data transfer and the potential to monitor the condition of the load cell to help with maintenance. All load cells have a different load cell price, depending on the performance needed. Irrespective of design and price, you can buy load cells of any kind at METTLER TOLEDO.

How accurate are load cells?

Very often accuracy and resolution are used interchangeably when talking about load cells. Resolution is how many digits are displayed, but more digits do not mean better accuracy. Accuracy describes how true the weighing results are (load cell accuracy calculation and load cell capacity calculation). For good reason, legal-for-trade scale load cells limit resolution to eliminate getting into the interpretation of results. Therefore, the best benchmarks for accuracy are legal-for-trade approvals. Load cell sensors typically provide accuracy from 1/3,000d up to 1/10,000d (also referred to in the load cell specifications). Load cells using force restoration reach 1/200,000 or even better. Under ideal conditions, which include constant temperature and humidity, the accuracy can be 5-10 times better.

But it is fairly complicated to calculate the final system accuracy of a load cell load cell scales. Many impacts like temperature, time, resolution etc. need to be considered. It is recommended to seek advice from load cell manufacturers. The Weighing Component Selector provides these calculations in a professional manner.

How do load cells fail?

Load cells failures can have multiple reasons. The most common source of failures are junction boxes in analog load cell systems. If such an analog load cell system fails, the troubleshooting can be cumbersome, because every load cell cable, load cell and the load cell junction box needs to be checked. Digital load cells eliminate this and many other sources of failures by providing diagnostic data. By processing the data you can be sure, your system is up and running and in case a load cell fails, the system will tell you which load cell is not responding.

How is load cell measured?

Load cells are used to measure the weight of any possible material (e.g. with a 50 kg load cell, 10-ton load cell, load cell 50 ton, load cell 100 ton, or any other capacity). They reach from microgram in load cell sensors to several load cell 100 tons in high capacity load cell scales. Low weights are required for pharma applications where fractions of a gram can make a key difference. Mid-size load cells are typically used for processing and trading materials (e.g. 5 ton load cells). Large capacities are used for storage applications.

How do I select a load cell? What do I need to know to select a load cell?

A common problem for using load cells is choosing the wrong protection. Load cells are very sensitive to humidity and regular wash-down. Although claiming a high IP rating the protection is not good for damp heat. When it comes to high humidity and sudden temperature changes (cold environment, hot wash-down) it is advised to always choose stainless steel hermetically sealed load cells. So different parameters need to be taken into account when you buy load cells.

Calibration costs for load cell systems are often underestimated. If your quality system requires regular calibrations of such weighing systems, seek advice for the most efficient method by METTLER TOLEDO. An ISO9001 complying method needs independent calibration equipment traceable to international standards. Under no circumstances, it can be assumed that calibration is never changing and a load cell scale does not need re-calibration at all. An efficient method calibrating larger tanks scales is RapidCal™.

Installing a load cell scale is often under-estimated on accuracy impact. In any case shielded cables are recommended since the load cell signal is very low voltage and easily disturbed. Choose the shortest cables possible as copper changes resistance over temperature and the lower cable resistance, the better.

Very often the integration of scale load cells is cumbersome and requires engineering knowledge. See details on how to select the right weigh modules and find the right load cell for sale.

What is the difference between load cell and strain gauge?

Strain gauges are components of load cells. Load cells are a counterforce that converts load into strain. That strain is taken by the load cell sensor, which changes its resistance into an electrical quantity that can be measured and reported as a weighing result. This is the same principle for 10 ton load cell and load cell 100 ton.

What is the purpose of a load cell?

Load cells measure force, sadly not masses which would be ideal. That leads to the fact that any other vertical accidentally occurring force in a load cell scale has direct impact on the accuracy. Typically piping forces in a vessel, contact to ground by e.g. debris collection, cable touching for loading cells and small capacity systems, vertical vibration etc. are mentioned. Touch base with an expert to avoid those problems in your system and find the right load cell for sale.

What is the output of load cell? How do you calculate load cell output?

Most load cells provide an analog output of 2-3 mV/V. Since these are passive devices, they need an external power source for excitation. The output signal varies related to the relative excitation voltage and current load. Thus, it is crucial to have a very stable excitation source that eliminates the effects caused by the power source. A 2mV/V load cell provides as little as 20mV output at full capacity when powered with 10V output. Modern terminals (load cell reader) provide both a stable power source and accurate amplification of the output signal to convert results into digital information. It is important for the signal to perform proper load cell wiring.

What is excitation voltage for a load cell?

Load cells are passive devices that need an external power source for excitation. Related to that excitation, voltage can change based on the current load, causing errors. Therefore, it is crucial to have a very stable excitation source to eliminate errors caused by the power source. Modern terminals provide a stable power source, accurate amplification of the small output signal, and conversion of results into digital information.

What is a hydraulic load cell?

Hydraulic load cells use the principle of pressure change when loading an enclosed fluid. The pressure change is measured by a pressure transducer. Hydraulic load cells are not very accurate and not very common these days. The advantage of robustness that they offered in times when electronics were not as accurate are long gone.

Are load cells linear?

Typically load cells are very linear to 0.03% or even much better. Scales today are primarily only calibrated at zero and a maximum span point indicating that the range in-between is linear.

How many load cells do I need? Would 1 or 2 load cells be sufficient for a 3 or 4 leg tank scale?

Using fewer load cells than tank legs is possible for liquid level control systems. The key is to ensure that the center of gravity in the system does not shift horizontally with load. Accuracy for such a system may not be ideal. Do not use such a system for bulk material.

Will a PT1000 or PT100 electronic work with analog load cells?

Analog load cells have a mV/V interface which is different from passive temperature sensors such as PT100, PT100, thus special electronics is required.

How do you calibrate a load cell?

Load cell sensors need to be calibrated where they will be used. The primary reason for onsite calibration is that gravity changes by location. A load cell manufactured in location A and used in location B would create an error without onsite calibration. Another reason onsite calibration is important is the ongoing wear on the device itself to which all technical instruments are subject. Depending on the importance of accuracy in the process in which the scale is used, it is good practice to calibrate a scale every 1-2 years.

What is a digital load cell? How do digital load cells work?

Load cell sensors need to be calibrated where they will be used. The primary reason for onsite calibration is that gravity changes by location. A load cell manufactured in location A and used in location B would create an error without onsite calibration. Another reason onsite calibration is important is the ongoing wear on the device itself to which all technical instruments are subject. Depending on the importance of accuracy in the process in which the scale is used, it is good practice to calibrate a scale every 1-2 years.

What is a load cell for weighing machine?

A scale load cell for weighing machines is used in a variety of industries in which precise measurements are needed. Load cells for weighing machines accurately measure the weight of tanks, vessels, hoppers, or conveyors. Load cell technology is built to withstand the demands of a variety of rugged industrial applications. The capacity of load cells for weighing machines can greatly vary. Some load cells are more appropriate for laboratory applications, while others are more appropriate for high-capacity batches or logistics applications.

Load cells for weighing machines shall meet all globally required approvals and standards. They include single-ended beam load cells that allow you to change your structure into a scale. Beam load cells are used in multiples in floor scales, belt weighers, weighing systems, pallet scales, checkweigher scales, and conveyor scales. Canister/ring load-cell technology features robustness for harsh environments as well. These are typically used in tank scales, vessel weighing, silo scales, and truck weighing.