X16 X-ray Inspection System

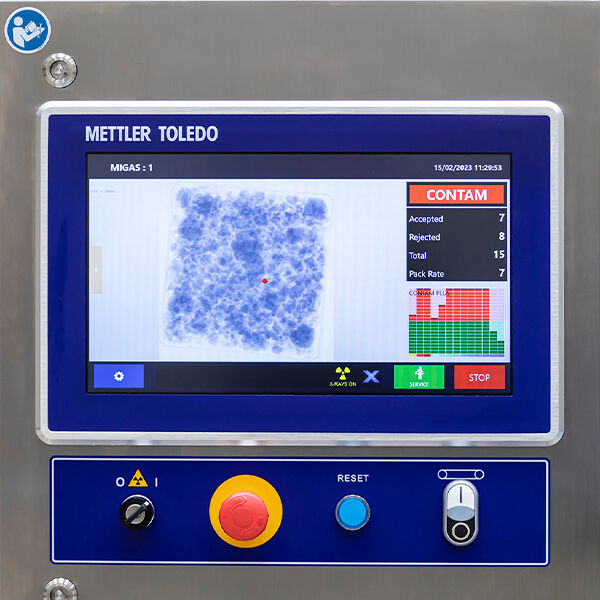

Safe, Accurate, and Complete Inspection.The X16 system is the prime solution for medium-large food, and pharmaceutical products. This innovative x-ray inspection system delivers enhanced product quality and improved product safety.

Detect a Wide Range of Contaminants

Beyond metal, the X16 can detect glass, stone, bone and many low-density materials.

Enhance Product Quality

Go beyond contamination detection, to perform a variety of product integrity checks to improve product safety and quality.

Increase Productivity

An intuitive interface paired with a front-opening design provides easy access for cleaning and maintenance, increasing uptime and productivity

Material No.: 30541252000

Features

Specifications

Specifications - X16 X-ray Inspection System

| IP Rating | IP65 IP66 IP69 |

| Compatible Software | ProdX |

| Connectivity | Ethernet OPC UA USB |

| Inspection Solution | X-ray Inspection |

| Max Product Width | 380 mm |

| HMI | 15.6" Touchscreen |

| Packaging Type | Cardboard Cartons Metalized Film Plastic Trays |

| Cooling Method | Air Conditioner |

| Product Flow | Conveyor |

| X-ray Beams | Single vertical beam |

| X-ray Generator | 100 W, up to 84 kV, up to 3.3 mA Glass Tube 420 W, up to 84 kV, up to 5.0 mA Glass Tube |

| Inspection Application | Clip Detection Completeness Check Contamination Detection Fill level Check Integrity Check Mass Control Product-Trapped in Seal |

| Product Characteristic | Medium-Large Packages |

| Industry | Chemical Food & Beverage Pharma & Biotech |

| Max Product Height | 200 mm |

| Industry Segment | Bakery and Confectionery Beer, Wine and Other Alcoholic Beverages Bulk Chemicals Cosmetics Dairy Fine and specialty chemicals Food Additives Meat & Poultry & Seafood Nutraceuticals Oils and Fats Pet Food and Animal Feed Pharma Ready Meals Snack Foods Sugar Starch and Yeast Water and other Non-Alcoholic Beverages |

| X-ray Detector | Single Energy, HiGain Technology |

| Max Product Weight | 25 kg |

| X-ray Emissions | < 1uSv/hr |

| Max Line Speed | 100 m/min |

| Max Throughput | 1000 ppm |

| Diode Size | 0.4 mm |