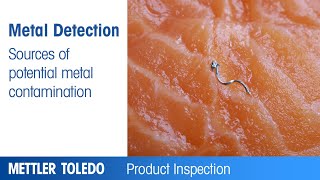

Refined Quality Control

We offer advanced systems for metal detection in food and pharma packaging to provide flexibility and high sensitivity when inspecting packaged products. Our metal detection systems can help you refine your quality control procedures and maximize the effectiveness of your production processes, as well as support compliance with industry standards such as the Good Manufacturing Practices (GMP).