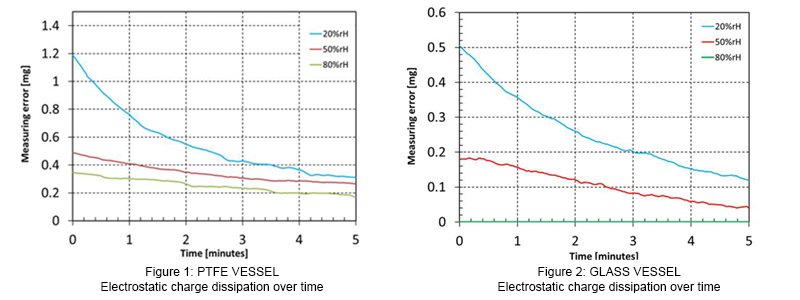

Understanding electrostatic charges and the effects they have on your samples and weighing vessels is critical to achieving good quality weighing results. Wherever possible, preventative action should be taken to reduce or eliminate the build-up of static charges on samples or weighing containers, in order to avoid any errors, instability or frustratingly slow weighing results.

What is static?

Static is the accumulation of electrical charges on the surface of a non-conductive material.

Managing static samples

Exciting new advances in weighing technology enable the latest generation of analytical balances to automatically detect the presence of electrostatic charges during a weighing operation. The magnitude of this force can be measured and recorded. Using an integrated ionizer module, these electrostatic charges can be eliminated to avoid any influence on the weighing result. As the static detection cycle is performed while the balance settles, and takes only a few seconds, it causes no delay in obtaining the weighing result.

Benefits for the balance user

StaticDetect™ simplifies the handling of statically charged samples or containers, making the process more efficient for the balance user, to ensure the highest accuracy and most reliable weighing results.