Watch this video to learn how automated in-line vision inspection systems verify alphanumeric, 1D and 2D barcodes on packaging surfaces and labels. Watch the video to learn how it works

Code Reading Vision Inspection Systems

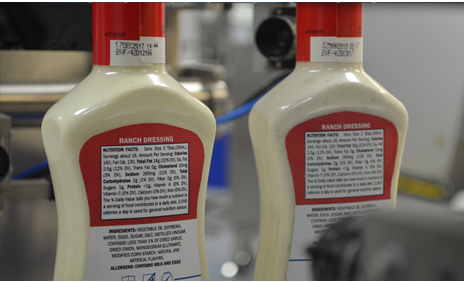

Check alphanumeric text, or 1D/2D codes on labels or packages

Guide to Code Check using Vision Inspection Systems

Secure Compliance with Industry Regulations

Product-specific codes, be they alpha-numeric or barcodes, serve a variety of functions on product packaging; for example, inventory purposes, supply chain security and facilitation of product recalls. It is critical that these codes are present and correct on product packaging in order to avoid unnecessary rework and product returns, along with the potential for fines or even lawsuits. Our systems help verify the readability of printed codes, ensuring compliance with industry standards.

Download White Paper:

Proven Code Reading Techniques

With so many ways to display product codes – often with multiple versions of the same code in different formats, having a system flexible enough to read multiple code types is required. Our vision inspection systems support a broad range of barcode formats and text fonts and possess the ability to read historically difficult formats such as dot matrix text.

Download White Paper:

Support for Round or Flat Containers

Product packaging can take any number of shapes, and while some products are oriented as they move along the production line, others may shift or even spin as they travel. Our systems are capable of 360° inspection, making locating and verifying codes on unoriented containers possible. Other system configurations can inspect codes on the top or bottom of product packaging, should it be necessary.

Download White Paper:

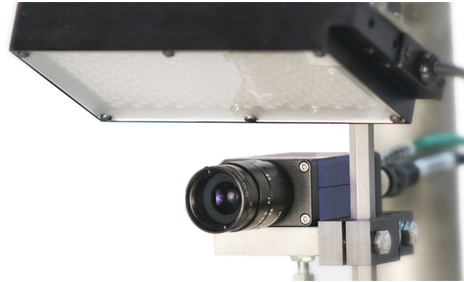

Smart Cameras and PC Based Vision System

Code reading applications are ideal for simple, easy-to-use Smart Camera systems. Our Smart Cameras provide fast and accurate code reading results, without the need for a more complicated solution. Depending on how many additional inspection applications are desired, a Smart Camera system can deliver results. More complex applications are handled by our PC based vision systems – speak with one of our vision experts to see which solution is right for you.

FAQs

What's the difference between OCR and OCV?

Optical Character Recognition (or OCR) is a method for identifying printed characters on a package surface. OCR is ideal for variable text fields, where it may not be possible to know what text string will be on the production line. The system compares a given character image against all the characters in a pre-defined font to find the closest match. Optical Character Verification, on the other hand, is looking for a pre-defined value – it is used to check for the accuracy of a code rather than determine what a code is. More information on the way that OCR and OCV work can be found in our white paper Making Codes Readable.

How are 1D and 2D barcodes read by cameras?

Cameras read barcodes in the same way that any barcode reader functions: the software analyses the contrast between filled and empty spaces in order to understand the shape of the code, and then decodes the pattern into an alphanumeric string. Depending on the code type, this either means analysing a simple horizontal line (as in a 1D barcode) or analysing a square (in the case of a 2D barcode). Either way, the basic principle of reading in a pattern of light and dark is the same. The advantage of using a camera instead of a more traditional barcode reader is that camera systems are better-suited to gauging barcode quality – a more traditional barcode reader can only really return a readable or undreadable result.

What is the difference between a PC vision system and a Smart Camera vision system?

Smart Cameras are completely self-contained systems which perform all the image processing and analysis work using an on-board CPU. Smart Cameras often feature integrated lighting as well, making them ideal for simple applications such as code reading. Unfortunately, this simplicity is not without its drawbacks – on-board memory is naturally limited, meaning that a comprehensive record of all products inspected may not be feasible. A PC-controlled system uses cameras which transmit images to a control PC which coordinates image capturing and processing. PC-controlled systems generally deliver faster processing times – which can be important for more complex applications – and carry the advantage of having far more memory to store different inspection profiles and inspection images.