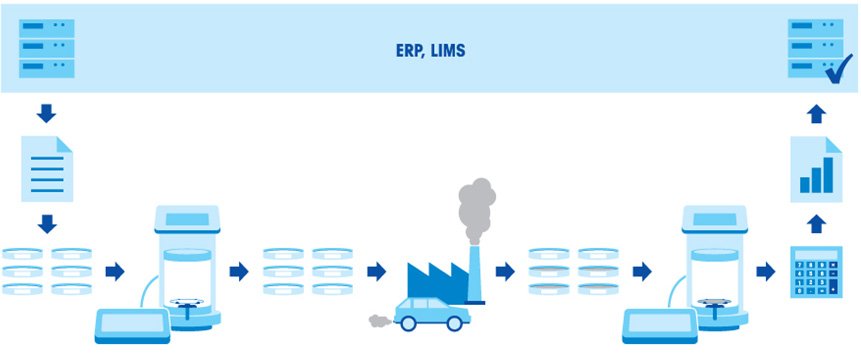

Whether measuring particulate matter in exhaust gases, evaporative emissions, the atmosphere or ambient air, the gravimetric filter weighing emissions test follows the same procedure.

1. A blank filter is first weighed on a balance in the laboratory.

2. Filters are loaded into labelled filter cartridges, preconditioned and transported to the test site.

3. At the test site, the air or gases are drawn through the filter at a known flow rate for a specific duration. Any particulate matter (PM) present is retained on the filter.

4. In the laboratory, the loaded filters are conditioned again and re-weighed.

5. By subtracting the weight of the blank filter, the mass of PM can be determined (differential weighing). Concentration of PM is calculated using the flow rate of the gas/air sample.

Whilst the test can be performed using just one filter, it is common practice to repeat the test several times as well as to retain a blank filter as a reference to eliminate background count. Filters may be used singly or in combination in a multiple-stage filter unit.

Emissions Testing Know-How

The World Health Organization (WHO) considers clean air "to be a basic requirement of human health and well-being" and provides guidelines for selected pollutants which are applicable across all WHO regions.

Emission standards set quantitative limits on the permissible amount of specific air pollutants that may be released from specific sources over specific timeframes.

In the U.S., CFR 40 Part 50 is part of the United States Code of Federal Regulations and concerns national air quality standards. The Occupational Safety and Health Administration (OSHA), part of the United States Department of Labor, published regulations (Standards – 29 CFR) concerning air quality, and the National Institute for Occupational Safety and Health (NIOSH) is also concerned with promoting safety and health at work.

The European Union sets legislation in the form of DIRECTIVE 2008/50/EC on ambient air quality and cleaner air for Europe; DIRECTIVE 2008/1/EC concerns integrated pollution prevention and control; and DIRECTIVE 89/654/EEC specifies the minimum health and safety requirements for the workplace.

The automotive sector is a key source of a variety of air pollutants including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), particulate matter (PM), as well as greenhouse gases (GHG). In both the European Union and in the United States, legislation exists to control emissions from motor vehicles and motor vehicle manufacturers are obligated to carry out emissions tests.

There are many methods and guidelines for testing emissions and particulate matter concentration. One of them is the gravimetric filter weighing method. Guidelines and regulations define the procedures to ensure accurate, reproducible filtering of emissions, and specify which filters should be used and which weighing system to use for the measurement as shown in the table below.

Examples of guideline requirements for weighing equipment and recommended balances:

Guideline |

Required

readability |

Required repeatability | Balance |

|---|

| Ultra-micro | Micro |

CFR 40

Part 1065 | Engine testing procedure | 0.1 μg | 2.5 μg /

0.25 μg | ✔ | |

|---|

| DIRECTIVE 2004/26/EC | Emission of gaseous and particulate pollutants from internal combustion engines to be installed in non-road mobile machinery | 1 μg | 2 μg | | ✔ |

|---|

| DIRECTIVE 2005/78/EC | Emission of gaseous and particulate pollutants from compression-ignition engines for use in vehicles and the emission of gaseous pollutants from positive ignition, engines fueled with natural gas or liquefied petroleum gas for use in vehicles | 1 μg (70 mm filter) / 0.1 μg (47 mm filter) | 2 μg | ✔ | ✔ |

|---|

It is foreseen that, as a result of increasingly tighter regulations combined with technological advancements in combustion engines, the amount of PM collected on filters will gradually decline. With guidelines typically specifying a balance with a readability of 1 μg or 0.1 μg, a highly accurate ultra-microbalance is therefore the only solution to meet both today's and future needs.