Investigation of the Cold Crystallization and Melting of Amorphous Linear Polyesters by ADSC

Introduction

Ever since its introduction in the early sixties, differential scanning calorimetry (DSC) has been used as one of the main techniques to study the crystallization and melting of polymers [1].

The cold crystallization and melting of polyethylene terephthalate (PET) was often analyzed with non-isothermal DSC measurements. The degree of crystallinity was then determined from the enthalpies of crystallization and melting by peak area integration [2, 3].

The aim of the present work was to study the crystallization and melting of polyesters using temperature-modulated differential scanning calorimetry (ADSC) and to point out the additional information that can be obtained with this method compared with conventional DSC.

Introduction

Ever since its introduction in the early sixties, differential scanning calorimetry (DSC) has been used as one of the main techniques to study the crystallization and melting of polymers [1].

The cold crystallization and melting of polyethylene terephthalate (PET) was often analyzed with non-isothermal DSC measurements. The degree of crystallinity was then determined from the enthalpies of crystallization and melting by peak area integration [2, 3].

The aim of the present work was to study the crystallization and melting of polyesters using temperature-modulated differential scanning calorimetry (ADSC) and to point out the additional information that can be obtained with this method compared with conventional DSC.

As has already been described elsewhere [4, 5], the ADSC technique is based on the superposition of a sinusoidal temperature program on a linear heating rate program according to the equation

T = T0 + β0t + AT sin (ωt)

where T0 is the initial temperature, β0 the underlying (or mean) heating rate, AT is the temperature amplitude and ω is the modulation frequency. The instantaneous heating rate, β, is given by

β = β0 + AT ω cos (ωt)

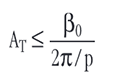

With crystallization and melting measurements, the instantaneous heating rate should always be positive, i.e. β ≥ 0. This is the case when the modulation parameters are chosen so that the condition

is satisfied, where p is the modulation period (p = 2π/ω). For example, if the underlying heating rate, β0, is 2 K/min, the condition β ≥ 0 is satisfied for the following pairs of values of AT and p: 0.159 K and 30 s; 0.318 K and 60 s; and 0.477 K and 90 s.

Modulation of the heating rate of course results in a modulated heat flow curve. Fourier analysis is then used to separate the curve into different components:

i) The total heat flow, φtot, which corresponds to the heat flow that would be obtained with conventional DSC at the same heating rate, β0.

ii) The phase angle, δ, between the modulated heat flow and the heating rate. This phase shift occurs during the ADSC measurement due to relaxation processes.

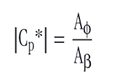

iii) A complex heat capacity, Cp* = Cp′ + iCp″, whose modulus is defined by the ratio of the amplitudes of the heat flow, Aφ, and the heating rate, Aβ, given by

The real and imaginary parts of Cp* are defined by the equations

Cp′ = |Cp*| cos δ

Cp″ = |Cp*| sin δ

The real part, Cp′, allows the so-called reversing heat flow, φrev, to be calculated through multiplication of Cp′ by βo. In the glass transition region, the phase angle, δ, is very small; cos δ is therefore close to 1 and Cp′ is practically equal to |Cp*|

Experimental Details

The samples measured were films of polyethylene terephthalate (PET) and polyethylene 2,6 naphthaline dicarboxylate (PEN). The ADSC analyses were performed using a METTLER TOLEDO DSC821e equipped with an IntraCooler cooling accessory. The results were evaluated with the STARe ADSC software option.

Summary

Both crystallization processes and the recrystallization process can be seen in the non-reversing heat flow curve up to about 265 °C. ADSC clearly shows the presence of two different crystal forms in this thermoplastic material. This effect has previously been studied by DSC and X-ray diffraction techniques [8].

Investigation of the Cold Crystallization and Melting of Amorphous Linear Polyesters by ADSC | Thermal Analysis Application No. UC 164 | Application published in METTLER TOLEDO Thermal Analysis UserCom 16