Below is a selection of recent continuous flow chemistry publications.

Wang Z., Gérardy R., Gauron, G., Damblon, C., Monbaliu, J-C., “Solvent-free organocatalytic preparation of cyclic organic carbonates under scalable continuous flow conditions”, React. Chem. Eng., 2019, 4, 17-26

Harper, K., Moschetta, E., Bordawekar, S., Wittenberger, S., “A Laser Driven Flow Chemistry Platform for Scaling Photochemical Reactions with Visible Light”, ACS Cent. Sci. 2019, 5, 109−115.

Schulze, P., Leschinsky, M., Seidel-Morgenstern, A., Lorenz, H., “Continuous Separation of Lignin from Organosolv Pulping Liquors: Combined Lignin Particle Formation and Solvent Recovery”, Ind. Eng. Chem. Res. 2019, 58, 3797−3810

Wang, Z., Gérardy, R., Gauron, G., Damblon, C., Monbaliu, J-C., “Solvent-free organocatalytic preparation of cyclic organic carbonates under scalable continuous flow conditions”, React. Chem. Eng., 2019, 4, 17-26

Dunn, A., Leitch, D., Journet, M., Martin, M., Tabet, E., Curtis, N., Williams, G., Goss, C., Shaw, T., O’Hare, B., Wade, C., Toczko, M., Li, P., “Selective Continuous Flow Iodination Guided by Direct Spectroscopic Observation of Equilibrating Aryl Lithium Regioisomers”, Organometallics, 2019, 38 (1), pp 129–137

Musio, B., Gala, E., Ley, S., “Real-Time Spectroscopic Analysis Enabling Quantitative and Safe Consumption of Fluoroform during Nucleophilic Trifluoromethylation in Flow”, Sustainable Chem. Eng. 2018, 6, 1489−1495

Gérardy, R., Emmanuel, N., Toupy, TY., Kassin, V-E, Ntumba Tshibalonza, N., Schmitz, M., Monbaliu, J-C., “Continuous Flow Organic Chemistry: Successes and Pitfalls at the Interface with Current Societal Challenges”, Eur. J. Org. Chem. 2018, 2301–235.

Strotman, N., Tan, Y., Powers, K., Soumeillant, M., Leung, S., “Development of a Safe and High-Throughput Continuous Manufacturing Approach to 4‑(2-Hydroxyethyl)thiomorpholine 1,1-Dioxide”, Org. Process Res. Dev. 2018, 22, 721−727.

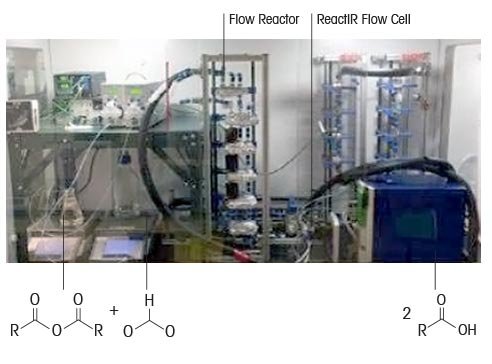

Das, U., Higman, C., Gabidullin, B., Hein, J., Baker, R.T., “Efficient and Selective Iron-Complex-Catalyzed Hydroboration of Aldehydes”, ACS Catal. 2018, 8, 1076−1081.

Fitzpatrick, D., Ley, S., “Engineering chemistry for the future of chemical synthesis”, Tetrahedron, 74, 25, 2018, Pages 3087-3100

Galaverna, R., Breitkreitz, M., Pastre, J., “Conversion of D-Fructose to 5-(Hydroxymethyl)furfural: Evaluating Batch and Continuous Flow Conditions by Design of Experiments and In-Line FTIR Monitoring” ACS Sustainable Chem. Eng., 2018, 6 (3), pp 4220–4230

Yang, H., Martin, B., Schenkel B., “On-Demand Generation and Consumption of Diazomethane in Multistep Continuous Flow Systems”, Org. Process Res. Dev. 2018, 22, 446−456.

Li, B., Guinness, S., Hoagland, S., Fichtner, M., Kim, H., Li, S., Maguire, R., McWilliams, J.C., Mustakis, J., Raggon, J., Campos, D., Voss, C., Sohodski, E., Feyock, B., Murnen, H., Gonzalez, M., Johnson, M., Lu, J., Feng, X., Sun, X., Zheng, S., Wu, B., “Continuous Production of Anhydrous tert-Butyl Hydroperoxide in Nonane Using Membrane Pervaporation and Its Application in Flow Oxidation of a γ‑Butyrolactam”, Org. Process Res. Dev. 2018, 22, 707−720.

Pedersen, M., Skovby, T., Mealy, M., Dam-Johansen, K., Kiil, S., “Redesign of a Grignard-Based Active Pharmaceutical Ingredient (API) Batch Synthesis to a Flow Process for the Preparation of Melitracen HCl”, Org. Process Res. Dev. 2018, 22, 228−235.

Hunter, S., Susanne, F., Whitten, R., Hartwig, T., Schilling, M., “Process design methodology for organometallic chemistry in continuous flow systems”, Tetrahedron, 74, 25, 2018, 3176-3182.

O’Brien, A., Ricci, E., Journet, M., “Dehydration of an Insoluble Urea Byproduct Enables the Condensation of DCC and Malonic Acid in Flow”, Org. Process Res. Dev., 2018, 22 (3), pp 399–402

Fitzpatrick, D., Maujean, T., Evans, A., and Ley, S., “Across-the-World Automated Optimization and Continuous-Flow Synthesis of Pharmaceutical Agents Operating Through a Cloud-Based Server”, Angew. Chem. 2018, 130,15348–15352

Hock, K., Koenigs, R., “The Generation of Diazo Compounds in Continuous‐Flow”, Chem. 2018, 24(42), 10571-10583.

Born S., Edwards, C., Martin, B., Jensen K., “Continuous, on-demand generation and separation of diphenylphosphoryl azide”, Tetrahedron., 2018, 74(25), 3137-3142

Ntumba Tshibalonza, N., Gérardy R., Alsafra, Z., Eppe, G., Monbaliu, J-C.,“A versatile biobased continuous flow strategy for the production of 3-butene-1,2-diol and vinyl ethylene carbonate from erythritol”, Green Chem., 2018, 20, 5147-5157

Thaisrivongs, D., Naber, J., Rogus, N., Spencer, G., “Development of an Organometallic Flow Chemistry Reaction at Pilot-Plant Scale for the Manufacture of Verubecestat”, Org. Process Res. Dev., 2018, 22 (3), pp 403–408

Pedersen, M., Skovby T., Mealy, M., Kim Dam-Johansen, K., Kiil, S., “Redesign of a Grignard-Based Active Pharmaceutical Ingredient (API) Batch Synthesis to a Flow Process for the Preparation of Melitracen HCl”, Org. Process Res. Dev., 2018, 22 (2), pp 228–235

Li, H., Sheeran, J., Clausen, A., Fang, Y-Q, Bio, M., Bader, S., “Flow Asymmetric Propargylation: Development of Continuous Processes for the Preparation of a Chiral b-Amino Alcohol”, Angew. Chem. Int. Ed. 2017, 56, 1–6.

Ntumba Tshibalonza, N., Monbaliu, J-C., “Revisiting the deoxydehydration of glycerol towards allyl alcohol under continuous-flow conditions”, Green chemistry, 2017, 13

Li, H., Sheeran, J., Clausen, A., Fang, Y-Q., Bio, M., Bader, S., “Flow Asymmetric Propargylation: Development of Continuous Processes for the Preparation of a Chiral β‐Amino Alcohol”, Angew. Chem. Int. Ed. 2017, 56

Plutschack, M., Pieber, B., Gilmore, K., Seeberger, P., “The Hitchhiker’s Guide to Flow Chemistry”, Chem. Rev. 2017, 117, 11796−11893