|

Table of Contents:

TA Tip

- Interpreting TMA curves

Applications

- Determination of the specific heat of dry substances of moist samples using ADSC

- Investigation of the thermal stability of CNx with TGA-MS

- Optimization of DSC measurement conditions

- Investigating the curing of amino resins with TGA-MS and TGA-FTIR

- Reproducible evaluation of DSC measurements: glass transition followed by chemical reaction

- Rapid thermogravimetric analysis of coal

Tips and hints

- TGA-FTIR and TGA-MS measurements

Determination of the specific heat of the dry substance of moist samples using modulated DSC (ADSC)

Introduction

Samples analyzed by Differential Scanning Calorimetry (DSC) often contain residual moisture (or, in general, solvent residues). In a conventional DSC experiment, the measurement curve then exhibits a broad endothermic evaporation peak. Such peaks often overlap other thermal processes, making the evaluation more difficult. In addition, solvent residues can influence other thermal effects. For example, residual moisture can act as a plasticizer and shift the glass transition of a sample to lower temperature. One way to separate the evaporation of residual moisture from other overlapping thermal effects is to use temperature modulated DSC. In ADSC, the linear temperature program is overlaid with a sinusoidal temperature modulation. This results in a sinusoidal heat flow. The analysis of such modulated heat flow curves allows overlapping effects to be separated. In this article, a possible procedure for the analysis of a pharmaceutical substance containing residual moisture is described as an example.

[…]

Investigation of the thermal stability of CNx with TGA/MS

Introduction

Carbon nitride (CNx) is a new type of material that is remarkable in having a degree of hardness similar to that of diamond [1]. Thin layers of this compound are routinely made at the Institute of Ceramics of the Chinese Academy of Sciences in Shanghai. The Chinese researchers wanted to learn more about the thermal stability of such layers and asked METTLER TOLEDO if they could help. Samples of the material were investigated in the METTLER TOLEDO applications laboratory in Schwerzenbach using a TGA/ SDTA851e coupled to a Balzers Thermostar mass spectrometer (MS).

[…]

Literature

[1] Cohen, M. L. , Phys. Rev. B 23, p. 7988, 1985

Optimization of DSC measurement conditions

Introduction

Semicrystalline polymers are normally characterized using DSC heating curves. The numerical values obtained with the technique are:

- Peak temperature (“crystallite melting point”)

- Peak area (heat of fusion)

The results depend to some extent on the actual measurement parameters used. But even under apparently identical conditions, certain variations in the results can be observed. The aim of this work was to establish the optimum measurement parameters using an elegant set of measurements.

[…]

Investigating the curing of amino resins with TGA-MS and TGA-FTIR

Introduction

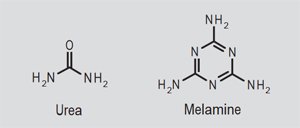

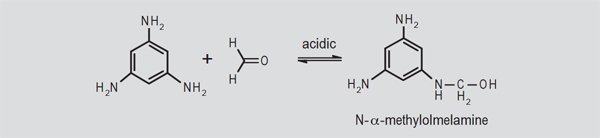

The monomers used for preparing amino resins (aminoplasts) are urea (for UF resins) or melamine (for MF resins) and formaldehyde. The latter undergoes an addition reaction with amino groups with the formation of N-methylol groups. In principle, with a primary amine, two methylol groups can be formed. With melamine (Fig. 1), the addition reaction of formaldehyde to the primary amine group (Fig. 2) is faster than to the secondary amine group; there is nevertheless the possibility of six-fold methylolation. Urea however only undergoes two-fold methylolation. Amino resins are available commercially in precondensed form, usually in aqueous solution, with molar masses of 500 to 1500 g/mol.

|

Fig. 1. Structural formulas of urea and melamine |

|

Fig. 2. Acid-catalyzed addition of formaldehyde to an amine group with the formation of a methylol group |

[…]

Reproducible evaluation of DSC measurements: glass transition followed by chemical reaction

Introduction

The reproducible quantitative determination of heats of reaction plays an important role both in quality assurance and in research and development. This necessitates both a careful measurement and a reliable evaluation procedure. In practice, it is often difficult to choose an optimum baseline when determining peak areas. This is particularly the case when different relatively small or broad thermal effects follow one another. This study presents a method for the reproducible evaluation of such DSC curves using the postcuring of an epoxy resin as an example.

[…]

Rapid thermogravimetric analysis of coal

Introduction

The quantitative determination of moisture, volatile compounds, chemically bound carbon, and ash content has long been used to determine the quality and economic value of different types of coal. High ash content is undesirable for the operation of thermal power stations because inert material increases transport and waste disposal costs, and also means that the heat exchangers have to be cleaned more frequently. To make sure that assays can be properly compared, the analysis procedures have been standardized and described in many standard methods [1-10].

Quite early on, measurement routines were developed for thermogravimetric instruments that enabled faster and more automated analyses to be performed. These techniques have been compared with the standard manual methods [11-14].

TGA (thermogravimetric analysis) is, however, also very useful for coal research, e.g. to compare combustion profiles or to determine the nature of volatile components with TGA-MS. Even the lime deposits (fur) formed in hot water systems have been investigated with TGA [15].

The determination of moisture, volatile content, soot, ash or fillers is also required for other applications. Analogous to the analysis of coal, a standardized thermogravimetric procedure is nowadays used to determine the content of elastomers, thermoplastics and thermosets, as well as lubricants [16, 17].

Conversely, procedures developed for the determination of carbon black in rubber [17] are used for the analysis of brown coal, lignite and or other renewable fossil fuels [e.g. 18].

[…]

Literature

- DIN 51718 Analysis of solid fuels - determination of water content and analysis moisture (in German).

- DIN 51719 Analysis of solid fuels - determination of ash content. (in German)

- DIN 51720 Analysis of solid fuels - determination of the content of volatile components. (in German)

- ASTM D3172 Standard Practice for Proximate Analysis of Coal and Coke.

- ASTM D3173 Standard Test Method for Moisture in the Analysis Sample of Coal and Coke.

- ASTM D3174 Standard Test Method for Ash in the Analysis Sample of Coal and Coke.

- ASTM D3175 Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke.

- ISO 11722 as well as BS 1016-104.1 Methods for analysis and testing of coal and coke. Proximate analysis. Determination of moisture content of the general analysis test sample.

- ISO 562 as well as BS 1016-104.3 Methods for analysis and testing of coal and coke. Proximate analysis. Determination of volatile matter content.

- ISO 1171 as well as BS 1016-104.4 Methods for analysis and testing of coal and coke. Proximate analysis. Determination of ash content.

- Richard L. Fyans, “Rapid Characterization of Coal by Thermogravimetric and Scanning Calorimetric Analysis”, Presentation at the 28th Pittsburgh Conference in Cleveland, Ohio, March (1977).

- John W. Cumming, Joseph McLaughlin, “The thermogravimetric behavior of coal”, Thermochimica Acta, 57 (1982) 253-272.

- F. S. Sadek, A. Y. Herrell, “Proximate analysis of solid fossil fuels by thermogravimetry”, American Laboratory, March (1984) 75-78.

- Danny E. Larkin, “The development of a standard method”, ASTM STP 997 “Compositional analysis by thermogravimetry”, C.M. Earnest, Ed., American Society for Testing and Materials, Philadelphia (1988) 28-37.

- Paul Baur, “Thermogravimetry speeds up proximate analysis of coal”, Power, March (1983) 91-93.

- ASTM E1131 Standard Test Method for Compositional Analysis by Thermogravimetry.

- ISO 9924 Rubber and rubber products. Determination of the composition of vulcanizates and uncured compounds by thermogravimetry.

- M.C. Mayoral, et. al., “Different approaches to proximate analysis by thermogravimetry analysis”, Thermochimica Acta, 370 (2001) 91-97