|

Ons technische handboek voor weegsystemen bevat ruim 150 pagina’s met feiten en allerlei andere informatie over toepassingen, zodat u een ideaal weeg- en voorraadcontrolesysteem kunt ontwikkelen.

Deze uitgebreide bibliotheek met informatie over tankweegsystemen en aangepaste weegschaalontwerpen helpt ingenieurs, operators en integratiespecialisten.

‘Weegmodulesystemen’ is het meest alomvattende handboek over het ontwerpen van moderne tankweegsystemen. Bent u ingenieur, operator of integratiespecialist en wilt u meer informatie over toepassingen en het gebruik van load cells voor tankweeg- en opslagsystemen? Dan is dit gratis informatiemateriaal in het Engels precies wat u zoekt! U kunt het gewoon downloaden.

Deze alomvattende informatiegids bevat ook een tabel met informatie over de chemische weerstand van meer dan 30 soorten staal, samenstellingen en afwerkingen tegen meer dan 400 chemicaliën, oplosmiddelen en materialen, om te garanderen dat het tankweegsysteem veilig gebruikt kan worden en lang mee zal gaan. Meer dan 10 extra bijlagen met handige informatie maken het proces voor het ontwerpen van een tankweegsysteem sneller en eenvoudiger dan ooit.

Het handboek bevat belangrijke informatie, zoals:

- Een beoordeling van de prestatiebehoeften en specifieke prestatievoorwaarden van uw tank-, platform- of transportbandsysteem.

- Technische berekeningen die rekening houden met de invloed van wind, seismische krachten, schokken, thermische effecten en load cell kabels.

- Het ontwerpen van aansluitingen voor het tankleidingwerk die geschikt zijn voor het frame en de basis.

- Kwalificatierichtlijnen voor het frame, de basis, de elektrische aansluitingen en het mechanische ontwerp die de hoogst mogelijke nauwkeurigheid garanderen.

- Een complete set technische specificaties voor toepassingen met compressie load cells, tension load cells, statische load cells en dynamische load cells.

- Kalibratie, verificatie en onderhoud garanderen de prestaties en de uptime van tankweegsystemen op de lange termijn.

- De verschillende load cell technologieën die beschikbaar zijn voor weegsystemen, en waarom bepaalde load cell technologieën beter zijn dan andere.

- Wat voor invloed heeft de kabellengte van een load cell op de meetresultaten van een tankweegsysteem?

- Algemene specificaties, zoals de nauwkeurigheid van de load cell en het materiaal van de load cell

- Hulpmiddelen zoals de berekening van de load cell nauwkeurigheid en de load cell capaciteit

|

Deze uitgebreide bibliotheek met informatie over tankweegsystemen en aangepaste weegschaalontwerpen helpt ingenieurs, operators en integratiespecialisten.

‘Weegmodulesystemen’ is het meest alomvattende handboek over het ontwerpen van moderne tankweegsystemen. Bent u ingenieur, operator of integratiespecialist en wilt u meer informatie over toepassingen en het gebruik van load cells voor tankweeg- en opslagsystemen? Dan is dit gratis informatiemateriaal in het Engels precies wat u zoekt! U kunt het gewoon downloaden.

Deze alomvattende informatiegids bevat ook een tabel met informatie over de chemische weerstand van meer dan 30 soorten staal, samenstellingen en afwerkingen tegen meer dan 400 chemicaliën, oplosmiddelen en materialen, om te garanderen dat het tankweegsysteem veilig gebruikt kan worden en lang mee zal gaan. Meer dan 10 extra bijlagen met handige informatie maken het proces voor het ontwerpen van een tankweegsysteem sneller en eenvoudiger dan ooit.

Weegmodule- en load cell-technologie verbetert de algehele efficiëntie

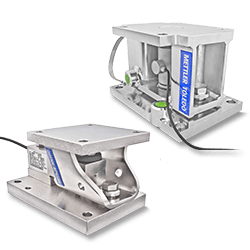

De load cell technologieën in het handboek omvatten de PowerMount™ weegmodule- en POWERCELL® load cell-technologie van METTLER TOLEDO. Deze load cell technologie levert informatie over voorspellend onderhoud om de Overall Equipment Efficiency (OEE) te verbeteren. De Condition Monitoring functie controleert continu de prestaties en merkt afwijkingen op voordat ze gevolgen hebben voor de productiviteit. Hierdoor behouden producenten controle over hun processen en worden fouten voorkomen voordat ze geld kosten.

Zonder de continue controle die POWERCELL® technologie biedt, kunnen fouten zoals load cell overbelasting, slechte communicatie tussen modules door beschadigde load cell kabels, fouten door symmetrieverlies en temperaturen die buiten het tolerantiebereik vallen, lange tijd onopgemerkt blijven. En als ze dan uiteindelijk opgemerkt worden, komt dat doordat de batches niet aan de specificaties voldoen of de productkwaliteit niet goed genoeg is. Dit veroorzaakt hoge kosten en is schadelijk voor het merkimago.

De PowerMount™ met POWERCELL® load cell technologie en ingebouwde microprocessors waarschuwen de operators niet alleen wanneer de prestaties verslechteren, maar passen het weegsignaal ook aan om te compenseren voor veranderingen in de productieomgeving. Hierdoor garanderen de PowerMount™ weegmodules nauwkeurige weegresultaten, ongeacht de temperatuur, lineariteit of hysterese. Mocht een load cell ooit defect raken, dan is het dankzij het ontwerp van de PowerMount™ heel eenvoudig om individuele load cells te vervangen. POWERCELL® is verkrijgbaar in allerlei verschillende capaciteiten. Het is ook belangrijk om op te merken dat wanneer u verschillende opties voor load cells onderzoekt, de prijs van de load cells slechts één van de overwegingen moet zijn. De load cell technologie, de load cell nauwkeurigheid, het load cell materiaal en allerlei andere factoren moeten in overwegingen worden genomen bij uw aankoop- en systeemontwerpbeslissingen.

Wat is een load cell kabel?

Bij een systeem met meerdere load cells is elke load cell via een load cell kabel met een junction box verbonden die de individuele signalen van de load cells samenvoegt tot één signaal dat naar de terminal kan worden gezonden. Analoog is de meest gebruikte bedrijfsstand, maar sommige weegschaalleveranciers leveren ook bedrijfseigen en niet-bedrijfseigen digitale bedrijfssystemen. Wanneer u een digitaal systeem gebruikt, kunt u de technische handleiding van de leverancier raadplegen voor de juiste bedrading van de junction box.

Gewoonlijk wordt elke load cell met een standaard kabellengte geleverd. U mag de load cell kabels voor uw installatie niet verlengen of verkorten. Als u de lengte van een load cell kabel verandert, dan heeft dat gevolgen voor het uitvoersignaal van de load cell. Als een kabel te lang is, wikkelt u de kabel op en legt u hem in of in de buurt van de junction box. U kunt junction boxes bestellen met afmetingen die groot genoeg zijn voor de opslag van gewikkelde kabels. U mag een loshangend stuk kabel nooit aan een actief onderdeel van het weegsysteem bevestigen. Als toepassingen kabels met een niet-standaard lengte vereisen, kunnen die apart worden besteld.

Hoe sluit ik een load cell aan? Hoe sluit ik meerdere load cells parallel aan?

Een load cell kabel wordt gebruikt om de load cell met de terminal te verbinden (een systeem met slechts één load cell) of met een junction box (een systeem met meerdere load cells / meerdere parallelle load cells). Bij analoge load cells is deze kabel gewoonlijk een integraal onderdeel van de load cell. In ons Engineering Handboek leest u hoe u een load cell aansluit en hoe u 4 load cells aansluit.

Wat is het verschil tussen een load cell met 4 of met 6 draden?

Load cells met 6 draden hebben extra spanningsgevoelige lijnen die onderdeel uitmaken van het load cell circuit; een load cell met 4 draden heeft die niet. De extra 2 draden van een load cell met 6 draden stelt de speciaal ontworpen terminals in staat om de ideale spanning te handhaven. Dit verbetert de systeemprestaties vergeleken met systemen met load cells met 4 draden, met name als de terminal verder van de weegschaal af staat.

Hoe installeer ik een load cell? Hoe monteer ik een load cell?

In ons Engineering Handboek staat algemene informatie over het installeren van een load cell of weegmodule met tips over de juiste montage van load cells en het ontwerp van de load cell bevestiging. Elke toepassing heeft unieke vereisten en moet gepland worden door een vakbekwaam bouwtechnicus. Wanneer u load cells of weegmodules installeert, moet u eerst de installatie- en onderhoudshandleiding voor het specifieke model lezen voor de juiste bevestiging van de load cell en het juiste ontwerp van de load cell bevestiging. Dat is het beste naslagwerk voor informatie over het installeren van een load cell.

Hoe installeer ik een compressie load cell?

Compressie load cells en compressie weegmodules zijn geschikt voor de meeste weegtoepassingen. Deze modules kunnen rechtstreeks aan de vloer, de pijlers of de structurele balken worden bevestigd. De tank of een ander voorwerp wordt bovenop de weegmodules gemonteerd. Voor de juiste installatie van compressie load cells leest u de installatie- en onderhoudshandleiding van het specifieke model. In ons gratis Engineering Handboek staan ook tips over de installatie van compressie load cells.

Waar krijg ik informatie over het bedraden van een load cell? Waar vind ik informatie over de load cell bedrading of een bedradingsdiagram voor load cells?

Er zijn allerlei overwegingen die u moet maken bij de bedrading van een load cell. Bij een systeem met meerdere load cells is elke load cell via een kabel met een junction box verbonden die de individuele signalen van de load cells samenvoegt tot één signaal dat naar de terminal kan worden gezonden. Analoog is de meest gebruikte bedrijfsstand, maar sommige weegschaalleveranciers leveren ook bedrijfseigen en niet-bedrijfseigen digitale bedrijfssystemen. Wanneer u een digitaal systeem gebruikt, kunt u de technische handleiding van de leverancier raadplegen voor de juiste bedrading van de junction box en voor informatie over het bedraden van een load cell of een bedradingsdiagram voor load cells.

In ons Engineering Handboek staat algemene informatie over het bedraden van een load cell met bedradingsdiagrammen voor load cells voor analoge of intelligente weegsystemen.

Waar kan ik een informatiegids over load cell toepassingen vinden?

Met behulp van een informatiegids over load cell toepassingen kunt u het juiste load cell ontwerp voor uw vereisten vinden. Wanneer u weegmodules voor een toepassing selecteert, is het belangrijk om te overwegen hoe het gewicht op de load cells zal worden toegepast. De meeste weegmodule-toepassingen voor tanks, hoppers en vaten zijn onderhevig aan een statische belasting. In normale omstandigheden wordt bij een statische belasting weinig of geen horizontale dwarskracht naar de load cells overgedragen. Toepassingen zoals transportbanden, leidingrekken, mechanische weegschaalconversies en krachtige mixers of blenders zijn onderhevig aan een dynamische belasting. Bij een dynamische belasting worden de load cells blootgesteld aan een horizontale dwarskracht vanwege de manier waarop producten op de weegschaal geplaatst of verwerkt worden. In ons gratis Engineering Handboek staat informatie over load cell toepassingen met uitleg over het selecteren van de juiste load cell of weegmodule voor uw weegtoepassing.

Hoe wordt een load cell meting in een totaalgewicht omgezet?

De meeste weegsystemen gebruiken een analoge junction box met een terminal die compatibel is met analoge systemen. Een analoge junction box kan de signalen van maximaal vier load cells met elkaar combineren en fungeert dus als een display voor een load cell. Voor weegmodulesystemen met meer dan vier load cells moeten meerdere junction boxes op elkaar aangesloten worden. In ons Engineering Handboek staat meer informatie over de manier waarop een load cell wordt aangesloten voor nauwkeurige gewichtsresultaten.

Hoe wordt de nauwkeurigheid van een load cell berekend?

De nauwkeurigheidsberekening van een load cell is ingewikkeld. Er bestaan diverse elektronische en mechanische tests die worden uitgevoerd conform een aantal metrologische of commerciële normen (naast standaard industrienormen). De onderliggende theorie is als volgt: een dun draadnetwerk (strain gauge) wordt aan een stuk metaal gehecht en elke verandering van de elektrische eigenschappen door verbuiging van het metaal wordt gedetecteerd. Het metaal moet op een reproduceerbare wijze worden verbogen, de strain gauge (het draadnetwerk) moet deze verandering op een reproduceerbare wijze als een signaal rapporteren en de terminal moet het signaal als een gewichtswaarde interpreteren. Wanneer we een referentiegewicht gebruiken dan moeten we de terminal laten weten dat de signaalverandering evenredig is aan de belastingverandering.

Wat wordt bedoeld met de load cell capaciteit?

De load cell capaciteit is het maximale gewicht dat de load cell kan dragen voor het leveren van nauwkeurige gewichtswaarden, zonder beschadigd te raken. De load cell capaciteit heeft gevolgen voor de load cell nauwkeurigheid van elke weegtoepassing.

Hoe wordt de capaciteit van een load cell bepaald? Hoe wordt de capaciteit van een load cell berekend?

De berekening van de load cell capaciteit bestaat uit verschillende elementen. De load cell is een sensor die de grootste en kleinste vereiste metingen moet kunnen uitvoeren. Daarbij mag de load cell niet defect raken wanneer de maximale belasting wordt toegepast en moet de load cell in staat zijn om de kleinste vereiste meting uit te voeren. Als het om weegmodules gaat, ofwel load cells plus extra technische hardware die speciaal ontworpen is om de toegepaste belasting te optimaliseren, en extra structurele functies kan hebben, dan is het vaak ook wenselijk om te voorkomen dat de weegmodule verschuift of omvalt. In elk geval is het nodig om de vereiste gewichten en krachten te kennen voor het handhaven van de structurele veiligheid en integriteit en het uitvoeren van de vereiste metingen, wat van essentieel belang is voor een succesvolle aanbeveling. De meeste technici zijn opgeleid om deze krachten te berekenen en wij leveren limietwaarden voor de maximale krachten waartegen onze modules bestand zijn, zodat de juiste keuze kan worden gemaakt.

Load cells meten zowel de stationaire belasting als de nettobelasting van een load cell weegschaal. Hiermee moet rekening worden gehouden bij de berekening van de capaciteit van een load cell weegschaal. De manier waarop de goederen op de weegschaal worden geplaatst, is ook van belang. Het gebruik van load cells die groter zijn dan nodig voor een specifieke toepassing wordt niet aanbevolen, omdat dat ten koste gaat van de nauwkeurigheid. Voor weegschalen waarop de goederen voornamelijk gecentreerd zijn, zoals de meeste vat-, silo en tankweegsystemen, is de formule als volgt:

C >= sf*(TDL+SC)/N (bijv. tankweegsystemen)

Voor weegschalen met vier load cells waarop de goederen waarschijnlijk niet in het midden worden geplaatst, zoals vloer- en transportbandweegschalen en kleine weegbruggen, is de formule als volgt:

C >= sf*(TDL/4 + SC/2) (bijv. vloer- en transportbandweegschalen en kleine weegbruggen)

C = capaciteit van de load cell of weegmodule

TDL = totale statische belasting

SC = weegschaalcapaciteit

sf = veiligheidsfactor (doorgaans 1,25)

N = aantal load cells of weegmodules