专业文库 Optimization of Selective Flow Chemistry

Optimization of Selective Flow Chemistry

This online seminar will provide an overview of continuous flow chemistry and how flow chemistry can be utilized to perform hazardous reactions in a safe and controlled manner. Chemistry examples where difficult and selective optimizations were performed using real-time FTIR analytical feedback will be discussed including hydrogenation, carbonylation and ozonolysis.

Continuous flow chemistry is one of the hottest topics in organic chemistry today. The number of scientific articles published on this subject every year is rapidly increasing and the top 20 pharmaceutical companies are continuing to invest significantly in continuous flow technology.

Continuous flow chemistry is one of the hottest topics in organic chemistry today. The number of scientific articles published on this subject every year is rapidly increasing and the top 20 pharmaceutical companies are continuing to invest significantly in continuous flow technology. Why is there so much excitement about continuous flow chemistry? Flow reactors:

- Use higher temperatures and pressures to access new chemistries and compounds

- Reduce reaction times from hours to minutes

- Increase selectivity and yields while reducing purification needs and waste

- Screen many different sets of conditions in one reaction - all with minimal amounts of potentially expensive or quantity limited materials

- Scale-up from milligrams to kilos with minimal optimization

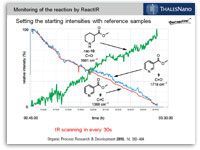

The combination of flow reactor technology and in situ analysis takes flow chemistry to another level. The formation of products, by-products and reactive intermediates can all be followed, and this information used to make ‘on the fly’ adjustments, which lead to optimized operating conditions of the whole system. Analysis no longer has to be done offline and optimum results can be achieved in minutes - saving valuable time and resources.

Guest Presenter

Richard Jones from ThalesNano, Inc.

Related Topics: flow chemistry, continuous flow chemistry, continuous processing, ReactIR™ 15, DS Micro Flow Cell, FTIR, real-time reaction analysis, iC IR™, iC software, continuous flow processes, in situ analysis