下面是部分连续流动化学出版物。

Kobayashi, Shū. "Flow “fine” synthesis: high yielding and selective organic synthesis by flow methods." Chemistry–An Asian Journal (2015).

东京大学的合成有机化学实验室出版,本文重点讲述了流动“精细”合成概念。 讲述了连续流动方法与批次方法相比的优点,以及流动方法面临的挑战。

Sans, Victor, and Leroy Cronin. "Towards dial-a-molecule by integrating continuous flow, analytics and self-optimisation." Chemical Society Reviews 45.8 (2016): 2032-2043.

本文主要关注用于合成化学的连续流动平台在工业和学术研究中的用法和优点,突出讲述了在此领域的重要贡献。

Mallia, Carl J., and Ian R. Baxendale. "The use of gases in flow synthesis." Organic Process Research & Development 20.2 (2015): 327-360.

达勒姆大学化学系出版,本文讲述了使用流动化学的优点,可以提高安全性以及研究效率。 本文还概述了将气体引入流动反应釜的各种方式,以及已经转变为流动方法的各种气体反应。

Ley, Steven V., et al. "Organic synthesis: march of the machines." Angewandte Chemie International Edition 54.11 (2015): 3449-3464.

剑桥大学化学系Ley研究小组出版,本文讲述了有机合成方法是如何变化的,以及这些方法如何帮助解决化学人员在研究实验室内面临的难题。

Baxendale, Ian R. "A short multistep flow synthesis of a potential spirocyclic fragrance component." Chemical Engineering & Technology 38.10 (2015): 1713-1716.

本文讲述了研究人员如何利用流动化学来帮助解决其合成难题,让放大生产变得更简单和更安全。

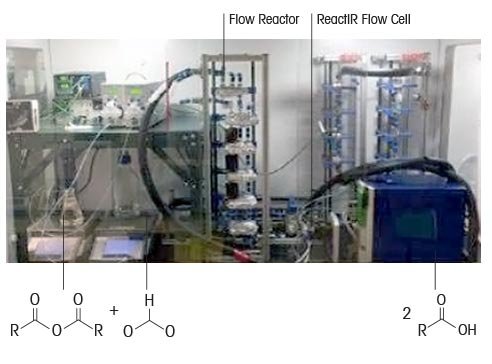

Hafner, Andreas, and Steven V. Ley. "Generation of reactive ketenes under flow conditions through zincmediated dehalogenation." Synlett 26.11 (2015): 1470-1474.

本文介绍了在流动条件下使用脱卤法制备高活性单烷基和苯基烯酮的方法。

Puglisi, Alessandra, et al. "Organocatalysis chemistry in flow." Current Organocatalysis 2.2 (2015): 79- 101.

近年来,有机催化在连续体中进行立体选择性反应已成为一种有效的方法。 立体选择性催化流动工艺可用于生产原料API和手性中间物。 本文讲述了使用有机分子作为催化剂的连续流动工艺的一些较新示例。 本文重点讲述了立体选择性工艺与固体负载催化技术在催化反应器中的应用,以及光氧化还原催化技术的应用前景。

Mueller, Simon TR, et al. "Safe handling of diazo reagents through inline analytics and flow chemistry." Chimica Oggi-Chemistry Today 33 (2015): 5.

通过在多步骤工艺中使用流动化学,可以针对大规模应用评估危险但有用的重氮基试剂。 重氮基化合物的产生、隔离和使用可连续进行,因此不会累积大量的高能量物质。

Hu, Te, Ian R. Baxendale, and Marcus Baumann. "Exploring flow procedures for diazonium formation." Molecules 21.7 (2016): 918.

本文讲述了如何使用流动化学提高安全性,如何使用连续制造确定形成重氮化合物的优化条件。

Atodiresei, Iuliana, Carlos Vila, and Magnus Rueping. "Asymmetric organocatalysis in continuous flow: Opportunities for impacting industrial catalysis." ACS Catalysis 5.3 (2015): 1972-1985.

本文重点讲述了使用连续流动化学执行的有机催化转换的优点,以及哪些反应已经成功。 比较了间歇应用和流动应用。

Müller, Simon TR, et al. "Rapid generation and safe use of carbenes enabled by a novel flow protocol with in-line IR spectroscopy." Chemistry–A European Journal 21.19 (2015): 7016-7020.

本文讲述了一种生成和使用施体/受体取代的碳烯的新连续工艺。 测定了重氮基团在苯乙酸甲酯上转移的安全特性,包括间歇和流动动力学研究。