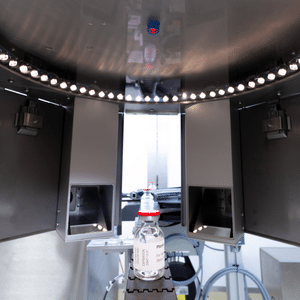

Configuration of 6 image sensors achieves 360° view of round packages in-line for aggregation into secondary packaging (boxes, cases, pallets). Eliminates the need for extra equipment to inspect codes typically printed onto lids or caps.

Aggregate Bottles, Vials or Cans

Allows easy aggregation of round containers into secondary packaging using a 360° inspection head.

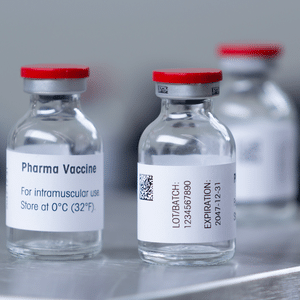

Accepts a Variety of Round Containers

Read codes on vials, bottles, cans or other round packages ranging in size from 10 mm to 110 mm on either a fixed focal lens or liquid lens.

Verify Small Detail Datamatrix Codes

Read codes as small as 0.2 mm per module using either a fixed focal lens or liquid lens 360° Inspection Head.

| Track & Trace Solution | Aggregation |

| Product Types | Bottles Vials Round |

| System Design | integrated |

| Reading Devices | Luminescence Sensor Smart Camera 360 Scanning Head Laser Scanner Smart Camera |

| Number of Reading Devices | up to 4 |

| Throughput | up to 300 ppm |

| Compatible Software | PLM Aggregation |

| Dimensions (H x W x D) | 394 x 589 x 510 mm |

| Product Height | max. 230 mm |

| Product Width | 6 – 110 mm diameter |

| HMI | 15″ 15″” |

Expedites aggregation of bottles into secondary cases, pallets or bundles with minimal impact to current production methods. Configure the PCE Software Suite to meet your connectivity needs for existing ERP, MES or cloud software solutions.

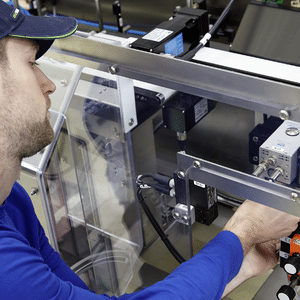

The adaptable 360° Inspection Head can either be mounted on a standalone frame or installed directly on existing production lines to reduce space. Select the HMI, cabinet or electrical enclosure to meet your needs.

Reads inkjet print (black or UV ink) that is standard in aggregation processes, where only the top lid or cap is exposed during production.

Helping you become compliant globally, meeting such standards as GMP (Good Manufacturing Practices), US FDA 21 CFR Part 11 practices or other regulations unique to your country or region.

Six image sensors fit into a compact IP65-rated stainless steel enclosure designed for minimum light interference for optimal readability of product codes on various printed surfaces such as labels, metal or plastics.

Helping ensure print quality and label errors are caught early, supporting inspection of labels for compliance.

A global network of service experts provide fast remote and on-site support. Our comprehensive service offer allows you to achieve regulatory compliance, high performance, and maximum uptime throughout the life cycle of your product inspection equipment.

Exclusive data-driven session on “Solving the Critical Pharmaceutical Supply Chain Challenges” with the latest research findings on industry trends and innovative technologies to address market needs.