We offer various measuring technologies that seamlessly integrate in a smart factory today or provide opportunities for the future.

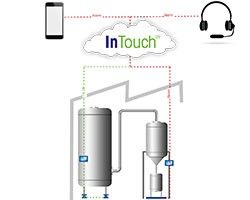

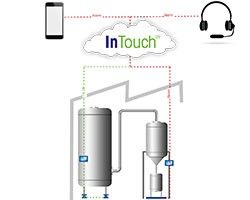

InTouchSM Remote Service

Remote monitoring of weighing processes avoids downtime. Remote support allows fast reaction and reduces the need for on- site interventions.

All data transfer is protected with third-party accredited security measures.

Terminals, Bench and Floor Scales

The weighing terminals for bench scales and floor scales show weighing results and feature self-learning functions plus status information, forwarding them to the control system or mobile devices of line operators.

Visit the IND570 Weighing Terminal

Weigh Modules for Small and Large Capacity

Small weigh modules and large weigh modules for tanks, conveyors or customized weighing devices feature an incorporated microprocessor to provide weighing results plus real-time status information to the control system.

SWB605 PowerMount™ Weigh Modules

Weight Transmitters to Integrate into Control Cabinet

Transmitters for DIN-Rail mounting provide very fast weight results plus comprehensive status information allowing priority setting for an alarm-management system via industrial-based Ethernet to PLC.

Get a quote for ACT350

Intelligent Sensor Management (ISM®) technology

Analytical sensors run sophisticated diagnostics to predict when maintenance, calibration or replacement is required. The latest version can actually learn from other sensors.

Sensors-That-Learn

Direct System Integration for Process Analytics Transmitters

With ISM-equipped transmitters, sensor diagnostics can be easily integrated into all common control architectures for monitoring on asset management software in a maintenance room.

ISM

Dynamic Product-Inspection Solutions

Scalable dynamic checkweighers, metal- detectors, x-ray and vision systems provide real-time status and production data to PLC or ERP systems via industrial fieldbus or OPC servers..

PI

High-Precision Weigh Modules for Small Capacities

High-precision weigh modules for automated weighing provide permanent weight values plus detailed status information. They feature incorporated calibration to perform functionality tests at any time.

WMF

Use Weighing Data to your Advantage

Collect+™ software captures production-weight and process data from every scale on your shop floor and visualizes it in an easy to understand dashboard. Use data for audits, quality initiatives and process optimization.